About Us

Many of us remember when the rag-and-bone man would tour neighbourhood streets on foot or with a cart shouting out for “any old iron” in his efforts to make a few bob.

Today, the scrap metal business is very much mainstream, professionally run, well regulated and successfully doing its bit for the environment by recycling huge amounts of scrap metal.

Bradford Waste Traders, which dates back to 1964, is now firmly established as one of Yorkshire’s leading scrap yards and waste metal recycling companies dealing in waste metals, iron, steel and non-ferrous products.

The business was originally known as D & R Sandham based at Horsforth, Leeds, before moving to Bradford in 1968 when it became Bradford Waste Traders and in 1986 Bradford Waste Traders Ltd. Operations cover three sites at Newgate Works, Bowling Back Lane; Back Muff Street; and Dick Lane Metals at Dick Lane.

The founders, David Sandham and Richard Sandham, started out from a butchering background, collecting livestock on a small scale before moving into scrap metal, rags and woollens collections.

David concentrated on the buying and selling of scrap while Richard ran the administrative side of the business and through hard work they had a successful partnership, and two generations of the family are now involved in the business which employs 35 people.

The two men were driven by an ambition to own their own farms and this was achieved with the purchase of a dairy farm, Town End Farm, near Yeadon in 1980, followed by the nearby Shaw Lane Farm in 1986.

Collectively they owned over 300 acres with parcels of land purchased when they came up for sale in the Yeadon and Guiseley areas.

Both the brothers’ shared the same interests in horses and cattle. Cattle were milked on the farms and other cattle were fattened for beef which was sold through local auctions weekly.

Peak figures saw more than 700 cattle and 500 breeding sheep on the farms.

The first yard’s in Bradford were located in Back Muff Street and known as the top and bottom yards.

It was so successful you would see customers queueing back down Back Muff Street waiting to unload. At this time they also hired out 25 horse & carts and would regularly take scrap to Sheffield Steel Works on an evening, in two wagons, one apiece. This is also where various business contacts were forged with other metal merchants further afield from Bradford.

It continued to be a busy time for the two men, who attended cattle auctions nationwide buying and selling, but the priority was the scrapyard. The business was growing and scrap yard was relocated to Newgate Works, a five acre main site on Bowling Back Lane.

This enabled the business to further grow its services across the region.

David retired due to ill-health in 2000 and passed away several years’ later. Richard and his sons’ bought David’s shares in the company from his family and carried on trading as normal.

Richard Jnr and James were given an early introduction to the business going in after school, during holidays and Saturday mornings. Richard Jnr started working full time in 1985 and James two years’ later and both learned all aspect of yard work including cutting scrap and working on the cranes.

In 1991 Richard Jnr started running Dick Lane Yard where horse and carts were still loaned out at a cost of £2 per day with an understanding that collected scrap had to be weighed in at the yard. It would then be sent to Newgate Works to be processed. Car spares were also sold at Dick Lane.

James went to work on the weighbridge soon after to work alongside Ralph Hudson who had run the weighbridge since the early days and he taught him how scrap was bought from customers.

Both Richard Jnr and James were also learning from their father and uncle who were hard taskmasters which shaped the young men with the necessary attributes needed for the future of Bradford Waste Traders Ltd.

In 2001, Richard Jnr returned to work alongside his dad at the Newgate Works, while Colin, Davids son, went to work at the Dick Lane yard.

The business was growing and by around 2005 was handling an average of 1,800 tonnes per week with Richard Jnr and James working long hours, sometimes starting at 4.30 am and working through until 8 pm such was the demand. By early 2008 scrap prices peaked to record highs only to plummet by October 2008.

The company was buying scrap and stockpiling it at this time and won an order with the Ford Motor Company to supply short cut steel which had to be no bigger than 18inch corner to corner which as a labourous task but profitable and lasted a few years until the process was moved abroad. Scrap bales were being sold to the UK steel works and foundries which have been longstanding customers. Processed scrap is currently sold to steel works for the manufacture of steel beams and construction industry products. Ferrous scrap is the core of the business and is also exported.

In 2015/16, the company, after research by James, bought a container tilter and based it at the Dick Lane site. After scrap is processed at the Newgate Works site, the ‘Tilter’ inverts the containers so scrap can be loaded into them, then they are shipped overseas to various global destinations.

This development has helped the company compete for the Yorkshire scrap which is known to be a fiercely competitive market.

Building a good relationship with customers and providing a speedy service has helped the business succeed and it aims to sell as much collected metal as possible for re-melting to enable it to be recycled.

Even today, Richard Jnr and James still expect to see or learn something different in the yards. They have seen ups and downs, plenty of characters and plenty of changes around the handling of metals. New machines and vehicles have been bought and machinery in use today includes hydraulic shears with pre-compression shears, which pre-compress scrap in a charging box before cutting the material to a required length to meet steelworks and foundry specifications. The fixed compression shears have a cutting force of up to 550 tonnes and are capable of processing up to 20 tonnes per hour.

Various types of fixed hydraulic balers are operated which can bale a car in seconds through to tin cans and aluminium.

The ferrous balers work under extremely high pressure to compress ferrous scrap into high-density bales ready for charging to furnace. Light steel, cuttings and wires are also baled.

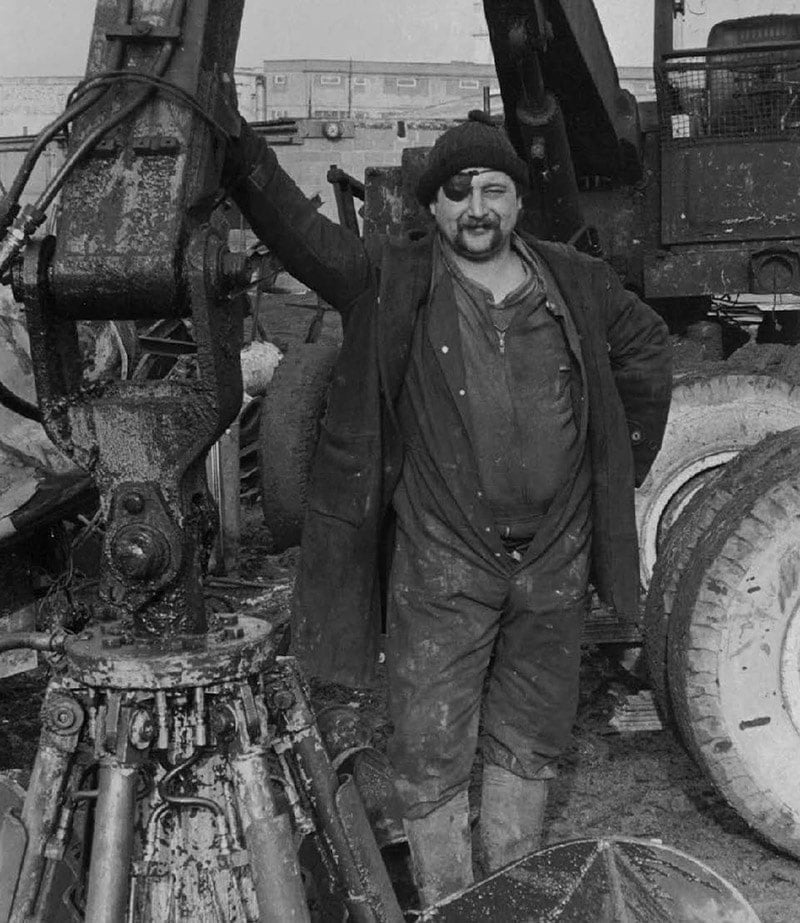

Many of the workforce have built up their skills through a longterm association with the company. One of the early employees recruited by David and Richard was Richard Gaunt who they met in Leeds. He ended up enjoying a long association with the company and had an active role in running the business until retiring to Australia in 2014.

Several staff are still with the business having moved from the Horsforth site with David and Richard to Bradford, and have been with the business 40 years. Many more joined from the local neighbourhood. Some, would help out in the yard after school and at weekends before getting full time jobs.

For many years scrap was often sold for cash but that was banned in December 2013 by the Government concerned that it fuelled metal theft. Cheques or bank transfer payments or now the preferred options with all dealings fully computerised.

The scrap metal industry has evolved into a highly specialised operation and BWT is keen to promote what it does to help increase waste metal recycling to the younger generation.

It is clear to see that Bradford Waste Traders, established by father and uncle, David and Richard Sandham, has continued to build successfully for well over 50 years and Richard and James are proud to carry on running the business in the same traditions.

Contact Us

If you’d like to learn more about our company and our history, or you want to get a valuation for all the waste metal you have lying around, simply give us a call or use our contact form and we’ll get back to you when we have a moment.

Accreditations